Advantages of RFID laundry tags

1. Labor costs can be reduced by more than 50%;

2. Visualization of clothing products to reduce the loss of fixed assets;

3. Supply chain management will reduce management time costs by more than 30%;

4. Improve the accuracy and reliability of stored information;

5. Efficient and accurate data collection to provide operational efficiency;

6. Automatic data collection to reduce human error;

7. Reduce the comprehensive cost of laundry washing management.

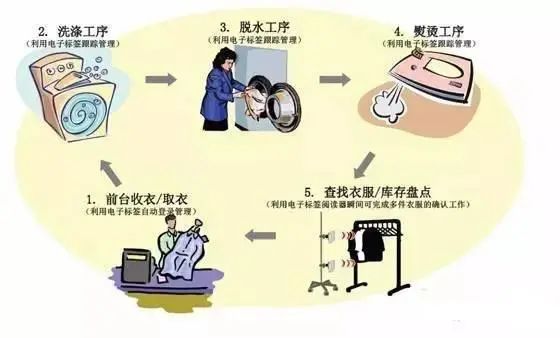

Wash companies use

Large washing companies take over a large number of orders every day, especially for duvet clothes in business hotels, bed sheets and clothing in hospitals, and even occasionally for bathing places. A large number of quilt products need to be washed, dried, ironed, folded and sorted before they can be handed over to customers. The process is complex and iterative. There are often many errors, which make people headaches, and for these problems, it is very necessary to build RFID systems and use RFID products.

Hospital use

Hospitals are faced with thousands of pieces of work clothes every year, the handover, washing, ironing, sorting, storage and other processes, how to effectively track and manage the washing process of each piece of clothing, the number of washings, the inventory status and the effective classification of clothes is a great challenge.

Common problems with hospital clothing

1. The handover of paper washing tasks is complex and difficult to query;

2. Worried about cross infection, the statistics of the quantity of some clothes cannot be carried out;

3. The amount of washing does not match the task;

4. Each step of the washing process cannot be accurately monitored, and the clothes are leaked

5. Accurate classification of washed clothes to save storage space;

6. It is not possible to accurately arrange the minimum safety stock per piece of clothing.

The hospital places RFID tags on patient clothing, staff overalls, surgical gowns, etc., which can achieve unified vertical management.